Top technologies for technical parts

Consumer articles, household goods, major appliances, electrical and electronic applications—application areas for technical parts are nearly endless. Color, material, surfaces or integrated functionality—plastics are able to showcase the full range of their special properties and benefits compared to other materials. KraussMaffei gives you access to the right machine technology and the appropriate manufacturing process for your application using years of experience and a wide portfolio of Injection Molding Machinery.

KraussMaffei's expertise reflects the diversity of applications involving technical parts with a comprehensive range of solutions across all machine series for Injection Molding Machinery. The EX series stands for uncompromising, high-quality production up to cleanroom standards. The CX series allows you to produce large numbers of pieces cost-effectively. As a flexible, reliable standard machine with automation engineered to the task at hand, the AX series also helps you lower energy costs, and subsequently production costs, while increasing product quality when producing technical components. And theGX series offers outstanding versatility for production in your applications with the most exacting precision and best article quality.

KraussMaffei does not just supply machines—we provide smart process engineering that helps you improve product quality and increase production efficiency. Expertise in multicomponent technology allows you to explore new possibilities in the production of injection molded articles for your company and to realize a significant increase in cost-efficiency using innovative solutions such as SpinForm technology or multi-daylight molds.

|

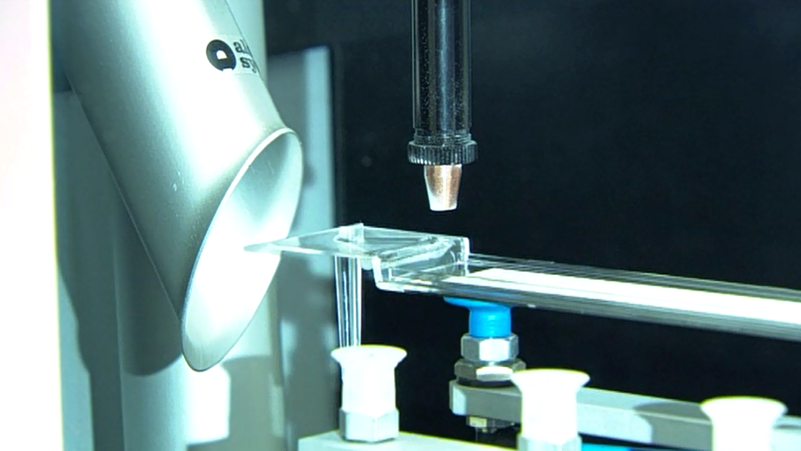

Surface technologies help you perfect the look, feel, design and functional integration of your components, allowing you to generate more added value. The CoverForm process developed together with Evonik, for instance, provides resilient components made of PMMA with optimal surface quality complete with a scratch-resistant coating applied right in the injection molding process. This lets you avoid later processing steps, significantly reducing your production costs. The ColorForm process from KraussMaffei is used to generate high-gloss surfaces for consumer electronics that draw attention with outstanding visuals, such as by presenting impressive depth effects in clear coat applications. ColorForm replaces typical painting steps and all upstream and downstream working steps, allowing you to obtain fully processed components with the finest high-gloss surface right from your production system. The paint is applied with precision in thin coats and uses minimal resources. |

|