Magbo

It is a system that you can safely use in automotive and electrical industries, pressure molding, clean rooms, rubber moulding, construction works and special moulding. Real clamping force reading, removable full metallic surface, temperature monitor, 30mm available option, slide detection system, tool recovery system and slide load rollers system are the most important qualities. Magbo specializes in permanent, electro-permanent and electro-magnetic technology covering the entire range of industrial magnetic technology available on the market today. Magbo is the perfect product for quick mold and die change in the plastic injection, metal stamping, die casting and rubber molding industry. With more 20 years manufacturing experience in the magnetic field, SOPH group will always offer the best technology for the application to meet our customer's needs.

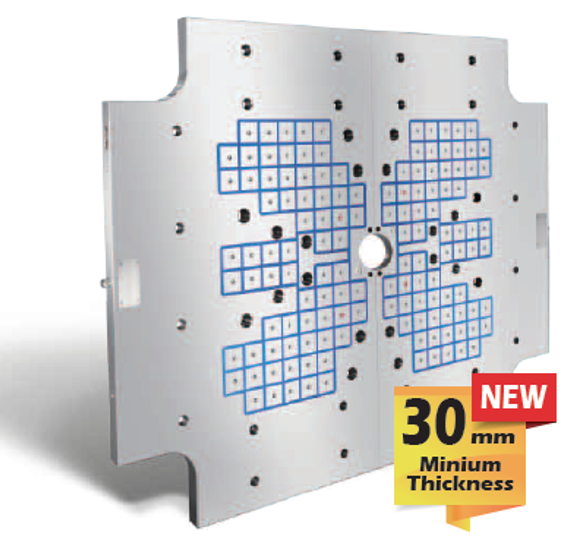

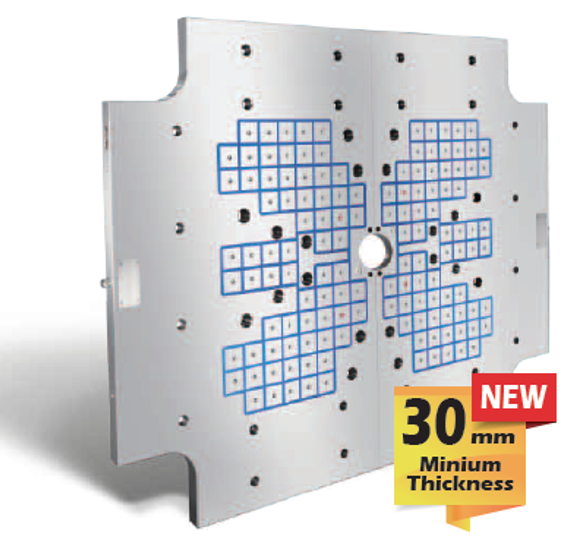

magbo saves daylight with the NEW slimline option. The new 30mm magnetic platens option saves valuable machine daylight and reduces injection mozzle extension requirements. Magnetic platen is more flexible when equipped with optional Removable Full Metallic Surface (5mm) allows fast and easy repairs of the magnet if necessary.

magbo saves daylight with the NEW slimline option. The new 30mm magnetic platens option saves valuable machine daylight and reduces injection mozzle extension requirements. Magnetic platen is more flexible when equipped with optional Removable Full Metallic Surface (5mm) allows fast and easy repairs of the magnet if necessary.

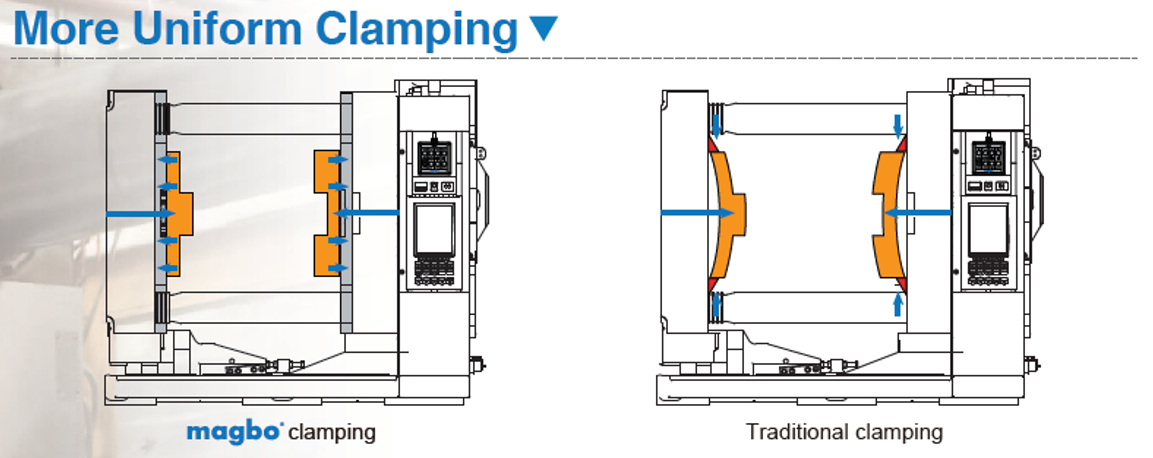

Traditional clamping focuses the clamping forces around the peripheral edges of the mold. Magnetic clamping generates clamping force over the entire surface of the mold. Once the mold magnetized it is nearly a part of the machine platen. This increased rigidity equates to higher parts, increased repeatability and less maintenance of the mold.

.

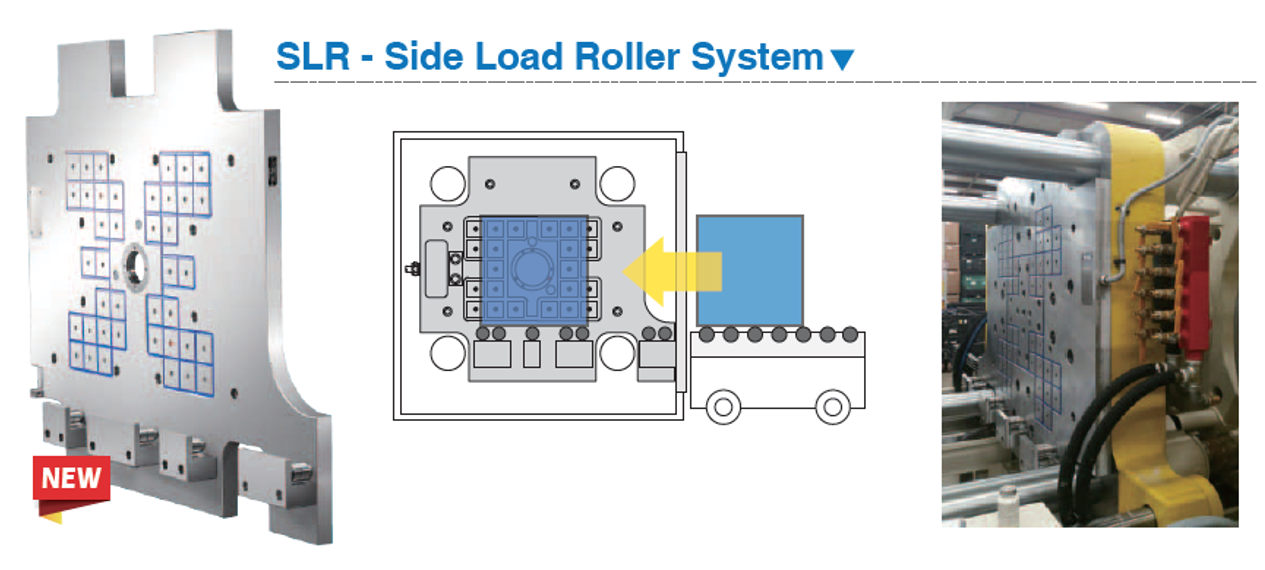

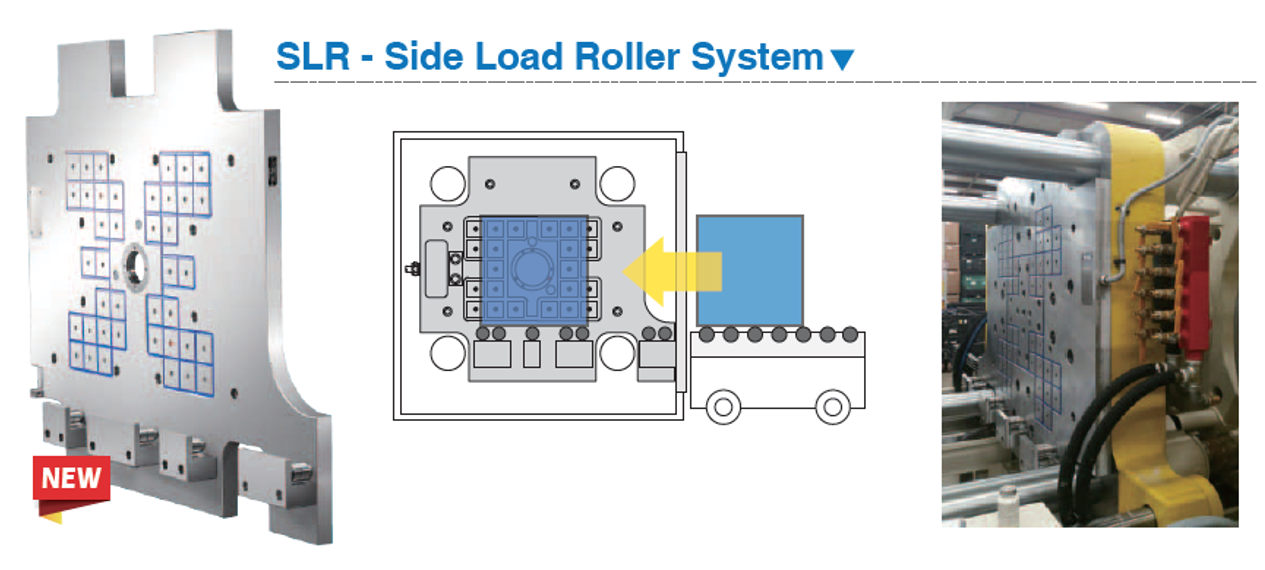

Magbo slide load roller system provides rollers outside the tie bars. It allows the molds to reach the mold cart over the tie bars of the press with no press modifications.

magbo saves daylight with the NEW slimline option. The new 30mm magnetic platens option saves valuable machine daylight and reduces injection mozzle extension requirements. Magnetic platen is more flexible when equipped with optional Removable Full Metallic Surface (5mm) allows fast and easy repairs of the magnet if necessary.

magbo saves daylight with the NEW slimline option. The new 30mm magnetic platens option saves valuable machine daylight and reduces injection mozzle extension requirements. Magnetic platen is more flexible when equipped with optional Removable Full Metallic Surface (5mm) allows fast and easy repairs of the magnet if necessary.