Success

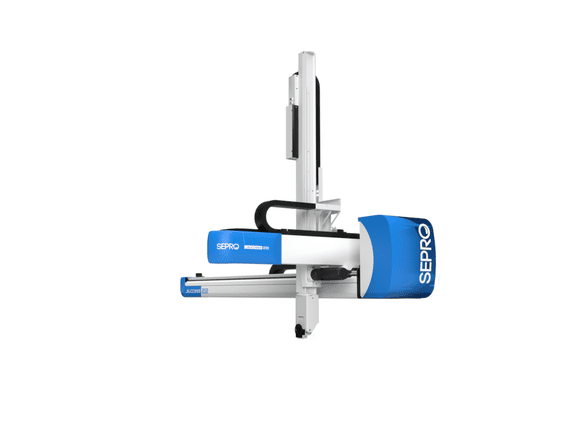

Success Series is Sepro’s universal robot line that delivers high performance and reliability standards in an economical and accessible design. This series ensures maximum efficiency in injection molding processes without compromising on quality and durability.

Completely redesigned by Sepro, the new Success Line is now also available with a 5-axis version. Known for its compact structure and enhanced gripping systems, this series is compatible with injection molding machines ranging from 60 to 900 tons. With increased payload capacity and a space-saving design, it brings high-end technology within easy reach.

Success Series – Key Features

• 3- and 5-axis operation options

• Next-generation Cam for follower technology

• Updated, modern, and functional design

• More compact structure with enhanced rigidity

• Improved gripping components

• Optimized structure for easier maintenance

• Higher payload capacity

• Extended axis travel for broader compatibility with IMM systems

Advanced Performance

The Success Series is a line of universal robots developed by enhancing the core advantages of Sepro’s best-selling model, Axess. It takes the success of Axess to the next level with longer axis travel distances and increased payload capacity.

Like the Axess series, the Success Series is equipped with the Touch 2 control system, offering a user-friendly interface, intuitive operation, and precise movement capabilities. This structure, which never compromises on reliability, adds durability and efficiency to your production line.

Thanks to the Simple Pick-and-Place Module, you can easily create your cycle by simply answering basic questions prompted by the system. The entire process can be instantly visualized in 3D on the screen, allowing you to quickly configure your production steps—whether it’s basic pick-and-place operations or structured stacking scenarios.

This user-friendly interface is an ideal solution for operators who want to manage robot operations without the need for complex programming knowledge.