MAGNETIC MOLD CLAMPING

Magbo Magnetic Quick Mold Clamping Systems offer innovative and safe solutions for plastic processing machines such as injection and blow molding. These systems stand out in various industries—including automotive, electrical-electronics, pressure coating, cleanroom applications, rubber molding, and custom manufacturing processes—with their advantages of high speed, safety, and efficiency. Thanks to the unique clamping force provided by the magnetic system, production times are reduced while operator safety is maximized.

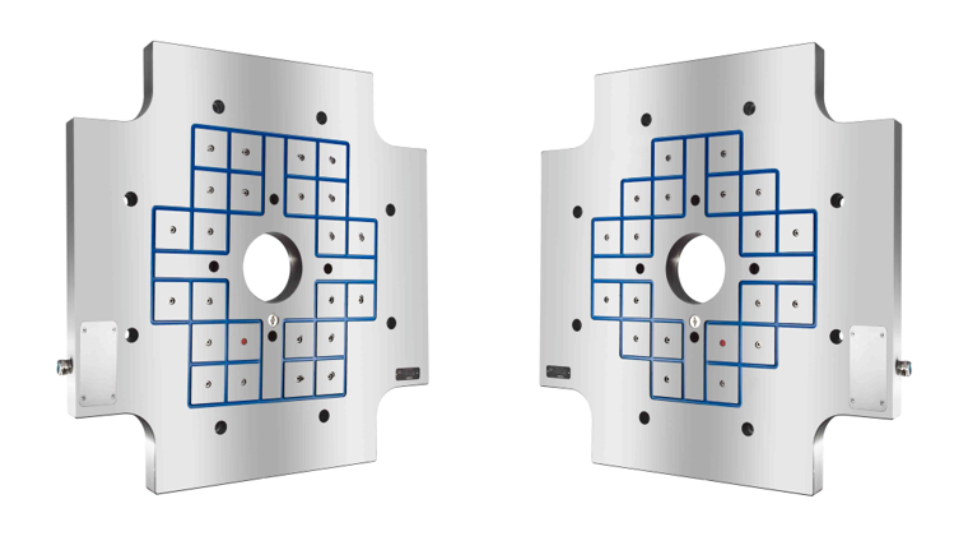

Magbo systems are equipped with numerous intelligent features such as real-time clamping force measurement, fully metallic removable surface, temperature control, optional 30 mm structure, slide detection, and mold rescue systems. Additionally, the side-loading sliding system allows mold changes to be completed with minimal effort and in a short time. This setup provides both operational ease and time savings on your production line.

With a modular design that can be integrated into any production line, Magbo solutions offer contactless, vibration-free, and maintenance-free operation to ensure production continuity. These systems are especially ideal for operations that require frequent mold changes, enhancing process safety while standardizing efficiency and quality.

As TEPRO Makine, we are the official distributor and authorized technical service provider for Magbo in Turkey. We are proud to offer complete Magbo solutions, including sales, installation, technical support, and spare parts services.