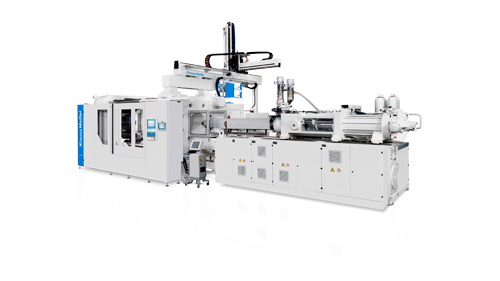

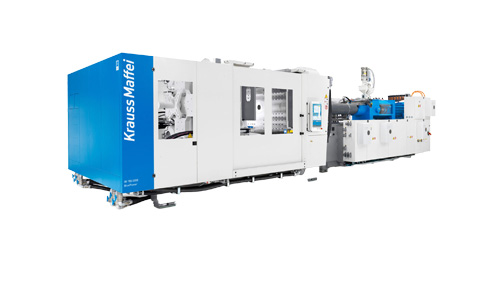

This system is typically a mechanism that ensures high-precision operation of the mold opening/closing unit in injection molding machines. In KraussMaffei’s all-electric machines, this structure enables faster cycle times and a more balanced clamping motion.

High-performance servo motor is optimized for fast mold movements and dynamic clamping force generation. Thanks to its precise resolution, mold movements occur in a highly controlled and repeatable manner. The precision control function that ensures mold safety enhances production security while preserving equipment longevity.

Equipped with energy-efficient drive systems, this structure offers safe and stable operation—especially for spring-loaded molds—through a braking clamp motor. The flexibility provided by servo technology improves process control and significantly reduces cycle times.

The MC P1 control system features a smart user interface that enables fast and precise navigation during injection processes. With its user-friendly design, it enhances operator control while saving time on production lines.

Thanks to its APC plus functions, it detects variations in material flow in real time and makes automatic adjustments to consistently ensure production quality. This system boosts efficiency while minimizing the margin of error.