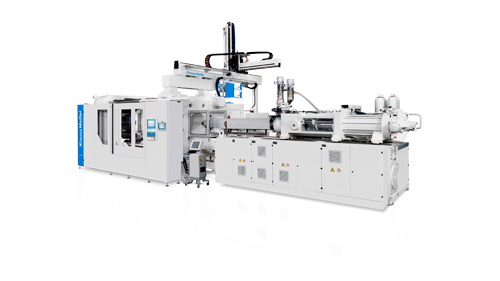

GX

SERIES

Leverage the first-class hydromechanical dual-platen concept of the GX Series together with its single-piston injection system to your advantage.

Thanks to its modular design, the compact dual-platen clamping unit can be configured with all available injection units to meet individual requirements.

This structure offers both flexibility and high production efficiency.

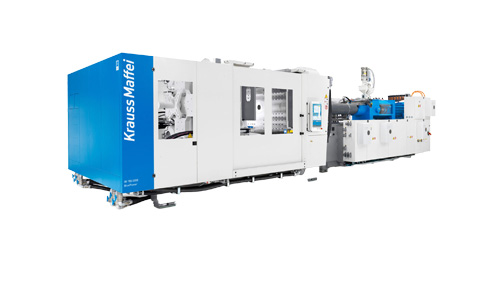

The GearX clamping system ensures that the mold is locked quickly and securely, reducing cycle times and increasing production speed.

The GuideX guide shoe perfectly absorbs the forces acting on the mold, extending mold life and enhancing process stability. Together, these two systems create ideal harmony between automation and machine, enabling high-precision and long-lasting production.

APC plus instantly detects fluctuations that may occur during the injection molding process and automatically compensates for them with higher speed and precision. This ensures that the production process is minimally affected by external factors and remains under continuous quality control.

Particularly ideal for cascade injection systems, this technology enhances production safety and helps achieve the goal of zero-defect manufacturing. With APC plus, process stability is ensured while maintaining both efficiency and quality.

The BluePower concept aims to minimize energy consumption during the production process, regardless of the technology used. Thanks to Vario and servo drive options, the system provides only the amount of power needed, precisely when it is required. This results in both energy savings and sustainable production.

The Energy Analysis Tool allows you to instantly see the impact of parameter changes on energy consumption. Through this transparent analysis, the performance and efficiency of your machines are optimized while significantly reducing energy costs.