STRONG

Thanks to standardized designs and high-tech components, the overall reliability of the system is significantly enhanced: SLS guides, motors, and speed drives are standardized across all our models. All essential sub-components are optimized and streamlined.

Pre-assembly and testing functions ensure easy installation and maintenance. With the Visual Control interface, the robot can be easily programmed and made production-ready in a short time.

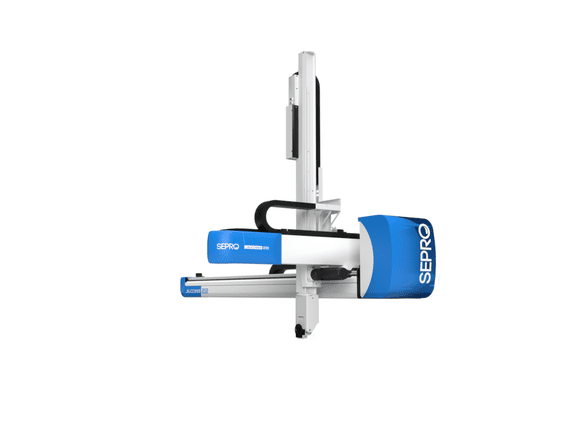

It is based on Sepro’s next-generation heavy-duty robot platform technology.

Designed to be compatible with stacking and feed-distribution peripheral systems.

Custom PLC (Programmable Logic Controller) integration is possible for every application.

The robot program can be synchronized with up to three sub-routines via PLC.

Up to 1,000 different applications can be managed (compared to 100 on the Touch 2 control unit).

Thanks to mold and EOAT (End of Arm Tooling) encoding, mold changes become completely safe.

Equipped with the Visual 2 control unit, the system is modular and can be upgraded over time.

The Z-arm with aluminum profile offers a high mass/stability ratio and provides a compact solution for applications with limited ceiling clearance.

Noise and maintenance needs are reduced, while savings are achieved in compressed air and electricity consumption.

Thanks to intelligent servo motor and brake control, a counterbalance cylinder is no longer required.

The large-section, single-beam demolding structure provides high stability and low moving mass advantages.

The prismatic guide on the Y-axis ensures an optimal balance between cost and stability.

Simultaneous management of 3 CNC axes minimizes mold intervention time.